Maximize a produtividade da sua fundição

Limpeza ideal na operação de fundição

Da mistura de linhas de separação à retificação de peças fundidas em areia queimada, a sala de limpeza da fundição apresenta desafios de produtividade que muitas vezes podem ser um gargalo no processo de fundição. Ter os abrasivos certos é fundamental – é por isso que a Weiler Abrasives oferece uma variedade de soluções específicas para aplicações de fundição. Nossa linha de abrasivos pode ajudá-lo a realizar trabalhos difíceis de desbaste e acabamento para diminuir os tempos de ciclo e, ao mesmo tempo, obter um acabamento de qualidade.

Vantagem da fundição cerâmica

A Weiler Abrasives está estabelecendo o padrão de desempenho no processo de fundição com sua tecnologia de abrasivos Tiger® Ceramic. Apresentando uma microestrutura ultrafina que se autoafia, esses produtos proporcionam desbaste ultrarrápido, altas taxas de remoção e maior vida útil do rebolo. A Weiler Abrasives oferece abrasivos para fundição de cerâmica em rebolos tipo copo Tipo 11 e rebolos tipo 27 e combinados, bem como cones, plugues e rebolos de retenção.

Solicite uma consultaType 27 Grinding Wheels

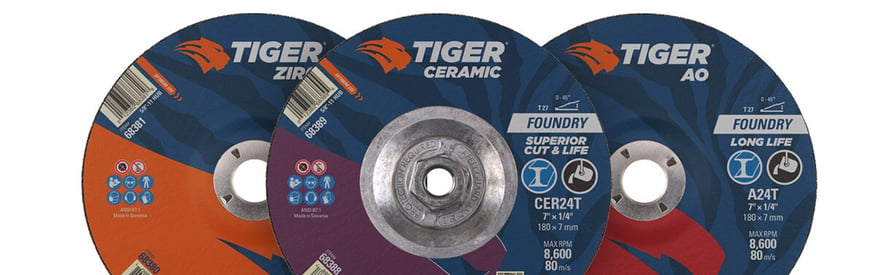

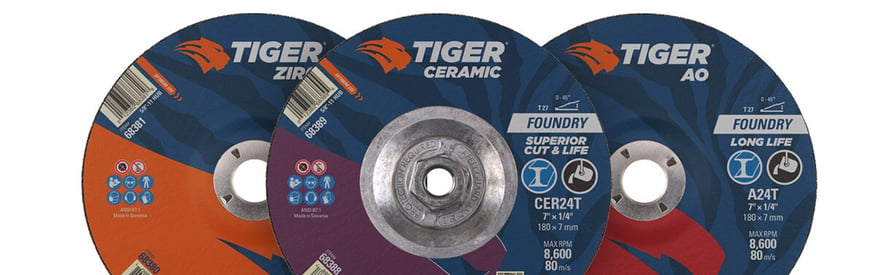

Tiger Ceramic has been specifically designed for tough metal foundry applications, offering superior cuts and long life. These depressed center wheels can remove up to 40% more material than competitive zirconia products, resulting in more uptime and fewer abrasives replacements.

Weiler Abrasives has also incorporated an advanced anti-chipping technology to improve operator safety in the foundry operation. It eliminates uneven edge breakage and chipping and reduces the chance of flying debris during grinding. The technology also lengthens wheel life and offers a reliable grinding edge, while a triple fiberglass reinforcement design further increases wheel strength.

Weiler Abrasives also offers the Tiger Type 27 grinding wheel in zirconia and aluminum oxide grain — both performance tiers, with the ceramic setting the highest standard.

Type 11 Flaring Cup Grinding Wheels

When compared to competitive zirconia cups, Weiler Abrasives industry-exclusive ceramic grain technology allow the Tiger Ceramic cup grinding wheels to cut up to 30% faster. This results in high metal removal and improved productivity in the foundry cleaning room, especially on hard-to-grind materials. A balanced cup design reduces vibration and operator fatigue.

Each cup wheel includes a Weiler Abrasives exclusive safety feature — an anchored hexagon nut that secures the cup in place, locking it to the tool. Operators can have peace of mind when working on the most challenging metal casting foundry jobs, knowing that the cup is secure and resists breakage. This zinc-plated nut also resists oxidation and compared to cups with standard metal backs, offers up to three times higher torque holding strength and withstands double speed burst test ratings.

Tiger cup wheels are also available in zirconia for fast metal removal, silicon carbide for burnt sand castings and alumina oxide grains for cast iron metal foundry applications.

Cones & Plugs

For use with straight grinders, Tiger cones and plugs provide an aggressive cut-rate from start to finish. They are ideal for ID cleaning, hole edge beveling, cleaning castings in hard-to-reach areas. Each cone and plug feature an anchored, heavy-duty steel hex nut to secure the abrasives to the grinder and improve operator safety.

Snagging Wheels

Tiger Type 1 portable snagging wheels for pneumatic straight grinders and high frequency electric straight grinders support heavy stock removal, rough beveling, and snagging. They are available in 3, 6- and 8-inch wheels with double fiberglass reinforcements to increase strength and resist chipping.

Weiler Abrasives offers the cones, plugs and snagging wheels for the foundry cleaning room including Tiger Ceramic, Tiger Zirc and Tiger AO. Each abrasive type and grain provide smooth, vibration-free operation to improve operator comfort and lessen fatigue. An open face design also provides aggressive cut-rate right out of the box.

Mounted Points

Ideal for cleaning IDs, complex geometries, hard-to-reach places and more, Tiger Zirc mounted points are available in a variety of shapes. They feature an engineered stem bonding for strength, stability and safety and have a dressed work surface, so operators don’t need to break them in.

Type 27 Grinding Wheels

Tiger Ceramic has been specifically designed for tough metal foundry applications, offering superior cuts and long life. These depressed center wheels can remove up to 40% more material than competitive zirconia products, resulting in more uptime and fewer abrasives replacements.

Weiler Abrasives has also incorporated an advanced anti-chipping technology to improve operator safety in the foundry operation. It eliminates uneven edge breakage and chipping and reduces the chance of flying debris during grinding. The technology also lengthens wheel life and offers a reliable grinding edge, while a triple fiberglass reinforcement design further increases wheel strength.

Weiler Abrasives also offers the Tiger Type 27 grinding wheel in zirconia and aluminum oxide grain — both performance tiers, with the ceramic setting the highest standard.

Type 11 Flaring Cup Grinding Wheels

When compared to competitive zirconia cups, Weiler Abrasives industry-exclusive ceramic grain technology allow the Tiger Ceramic cup grinding wheels to cut up to 30% faster. This results in high metal removal and improved productivity in the foundry cleaning room, especially on hard-to-grind materials. A balanced cup design reduces vibration and operator fatigue.

Each cup wheel includes a Weiler Abrasives exclusive safety feature — an anchored hexagon nut that secures the cup in place, locking it to the tool. Operators can have peace of mind when working on the most challenging metal casting foundry jobs, knowing that the cup is secure and resists breakage. This zinc-plated nut also resists oxidation and compared to cups with standard metal backs, offers up to three times higher torque holding strength and withstands double speed burst test ratings.

Tiger cup wheels are also available in zirconia for fast metal removal, silicon carbide for burnt sand castings and alumina oxide grains for cast iron metal foundry applications.

Cones & Plugs

For use with straight grinders, Tiger cones and plugs provide an aggressive cut-rate from start to finish. They are ideal for ID cleaning, hole edge beveling, cleaning castings in hard-to-reach areas. Each cone and plug feature an anchored, heavy-duty steel hex nut to secure the abrasives to the grinder and improve operator safety.

Snagging Wheels

Tiger Type 1 portable snagging wheels for pneumatic straight grinders and high frequency electric straight grinders support heavy stock removal, rough beveling, and snagging. They are available in 3, 6- and 8-inch wheels with double fiberglass reinforcements to increase strength and resist chipping.

Weiler Abrasives offers the cones, plugs and snagging wheels for the foundry cleaning room including Tiger Ceramic, Tiger Zirc and Tiger AO. Each abrasive type and grain provide smooth, vibration-free operation to improve operator comfort and lessen fatigue. An open face design also provides aggressive cut-rate right out of the box.

Mounted Points

Ideal for cleaning IDs, complex geometries, hard-to-reach places and more, Tiger Zirc mounted points are available in a variety of shapes. They feature an engineered stem bonding for strength, stability and safety and have a dressed work surface, so operators don’t need to break them in.

Programa de produtividade de consumíveis:

Este programa permite que os especialistas da Weiler Abrasives coletem dados no local, avaliem o uso de abrasivos e ofereçam recomendações para abrasivos que otimizam a retificação e melhoram o rendimento.

Treinamento de segurança SPOT

A Weiler Abrasives oferece treinamento de segurança baseado em SPOT (velocidade e tamanho, pressão, orientação, tempo) para ajudar os operadores a aprender a maneira adequada e segura de usar abrasivos.

Produtos projetados e soluções personalizadas

Para aplicações desafiadoras de fundição de metal, a Weiler Abrasives pode oferecer produtos ou avaliações de engenharia personalizada para fornecer soluções para problemas difíceis.

Nosso Compromisso

A equipe da Weiler Abrasives está comprometida em ajudar fundições como a sua a eliminar gargalos no processo de retificação para que você possa aumentar a eficiência da produção, atender às expectativas dos clientes e melhorar a lucratividade. Agende hoje mesmo uma consulta com um especialista em abrasivos e vamos encontrar suas melhorias.